Capital Equipment

PREP BAYS

Lowbake is the leading manufacturer of spray booths and baking ovens in Australia, using the latest technology and services available. This means our customers can have the confidence that their new purchase follows all standards as set by government regulatory authorities, and follow all occupational health and safety guidelines.

All products are designed using CAD (Computer Aided Design) software to any specifications that our customers require, allowing us to produce accurate and efficient layouts and designs for our customers. This leads to efficient installations, and any modifications, large or small, can be made immediately with little ease. This leads to minimal downtime during the installation phase and reduces disruptions to your business, reducing costs. On top of this, Lowbake has many distributors across Australia and the Pacific, including Asia, which means we provide full servicing and installation of all products nationwide.

Lowbake Aluminium Repair Room

The Lowbake Aluminium Repair Room is designed to enable efficient repairs of aluminium vehicles without risk or metal contamination. The large cabin has 2 wide sliding doors that allow a vehicle to be wheeled in on trolleys or straightening benches.

The machinery has a 2-speed air flow design with slow speed selection for general working and gluing operations. In this mode, electricity is made available through single three phase power points.

Features

- Lighting

- Power Points

- Tool Cabinets

- Filter Regulator

- 2 Sliding Doors Viewing Windows

- Paint Pocket Filters

- Spray Air is Available

- 2 Speed Air Flow System

- Integrated Power Lock Out

- Fully Insulated and Painted Cabin

- Repairing of Aluminium Vehicles

- Minimises Risk of Metal Contamination

Partitioning Curtains

All partition curtain walls are manufactured from high performance, flame retardant PVC polyester vinyl plastic and are custom designed to your particular requirements.

Curtain seams are high frequency welded for maximum durability.

Features

- Higher productivity

- Maximum durability

- Flexible work areas

- Confining contaminants

- Improved appearance

- Effortless sliding action

- Seperation of work areas

- Cleaner work environment

- Simple and quick connections

- Can be installed in wash bay areas

- Can be installed in preparation areas

- Curtain seams are high frequency welded

Stainless Steel Work Bench

Lowbake manufacture a wide range of stainless steel paint mixing benches and cupboards to store and mix paint safer.

The proven design of exhaust ventilation through the bench top is the most efficient way to remove hazardous vapors from the direct source of mixing. We recommend that any paint or solvent be opened and decanted with back ventilation.

Features

- Island Benches

- Wall Mounted Benches

- Keyboard Draw Model

- Computer Mounted Models

- Under Bench Storage Cupboards

- Sizes Range from 900mm to 3600mm long

- Ventilated & Non Ventilated

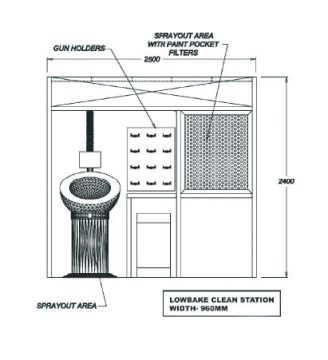

Clean Station

The Lowbake Clean Station is the ideal solution for solvent extraction & small colour sample spraying in complete safety.

Any model of gun cleaning machine can be installed in the Lowbake Cleaning Station. Using the Lowbake Infrared test sample drying unit will give your paint shop excellent quality and efficiency. The system is a gun wash and storage area combined with a small parts spray booth.

Features

- Time saving

- Well organised

- Filter regulator

- Spray gun holders

- Flat pack or installed

- Fully ventilated area

- Stainless steel bench

- User friendly and efficient

- Clean work place environment

- Ideal for sprayout colour cards

- Gun wash storage compartment

- Galvanised finish or powder coated

- Combination of gunwash and spray out

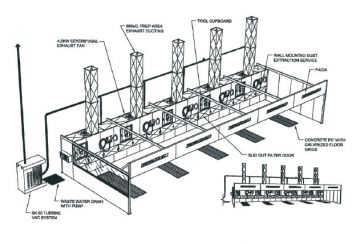

Prep Bay + IR

Lowbake are the industry leaders in designing and manufacturing Preparation Areas for the refinish Trade.

The preparation areas can either be down-draught or end-draught, depending on the location of the installation. All preparation bays have individual exhaust fans and ducting.

The preparation bays are designed to take paint spotting operations external of the spraybooth for reduction of bottle necks and increased efficiencies.

Features

- Super efficient down draught

- Galvanised ergonomic steel flooring

- Rear wall mounted slide out filters

- Super quiet 4kw exhaust fan

- One exhaust fan per bay

- Individual compressed air supply point

- Individual ducted vacuum system

- Optional - over head angled lighting

- Optional - tool cupboard with glass door

- Optional - sliding rail infrared system

Preparation Bays

The Lowbake Down-Draught Preparation Bay is a combination of a down-draught air flow area with an integrated vacuum system for sanders and an integrated sliding rail mounted infrared heaters for product curing.

This proven design provides the ideal work environment for all your panel filling, sanding, priming and paint spotting of motor vehicles and parts. The highly organised and ergonomic system allows maximum output in any paint shop.

Features

- Full down draught

- Galvanised ergonomic flooring

- Rear wall mounted side filters

- Optional Lockable tool cupboards

- Turbine power duct vacuum

- Integrated to the Prep Bay

- Super quiet large exhaust fans

- Rail mounted infrared curing system

- Breathe and spray air system

- Optional - over head angled lighting

Rear Wall Extraction Prep Bay

The Lowbake Rear Wall Extraction Preparation Bay is a cost efficient area suitable for sanding preparation and paint spotting on vehicles and parts.

This particular design does not need a concrete pit. The Rear Wall Extraction Preparation Bay has a ceiling with lights and the airflow is horizontal across the vehicle. The exhaust is through low level polyester exhaust filters. The prepbay is fitted with a ducted vacuum system with an integrated spray air in each bay for efficiency.

Features

- Super quiet

- User friendly

- Proven design

- Easy to maintain

- Modular construction

- Product curing system

- Fluorescent lights

- No concrete pit required

- Sliding infrared rail system

- High efficiency exhaust fan

- Integrated sanding vacuum

- Over head tri phosphorus colour

- Easy to change rear exhaust filters

Extraction Wall

The Lowbake Extraction Wall Prep Area is a simple low cost extraction unit for sanding as well as a preparation area.

The unit is fitted with paint pocket polyester exhaust filters to stop dust emissions. The large span filters allow for work to be carried out on varying sizes of parts.

Features

- 4kw Fan

- Super Quiet

- Easy to Install

- Low Maintenance

- Low Running Costs

- Modular Construction

- Polyester Exhaust Filter

- Suitable for varying sized of applications

Prep Wall with Integrated Cupboard

- Fully Assembled

- Super Quiet Fan - 4KW 3 Phase 400V 50hz

- Integrated Storage Cupboard

- Modular Design